ROLL-ON FILLING AND CAPPING MACHINE

Our company aims to be a “solution partner” rather than a supplier with its focused product range and design studies.

ROLL-ON FILLING AND CAPPING MACHINE

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

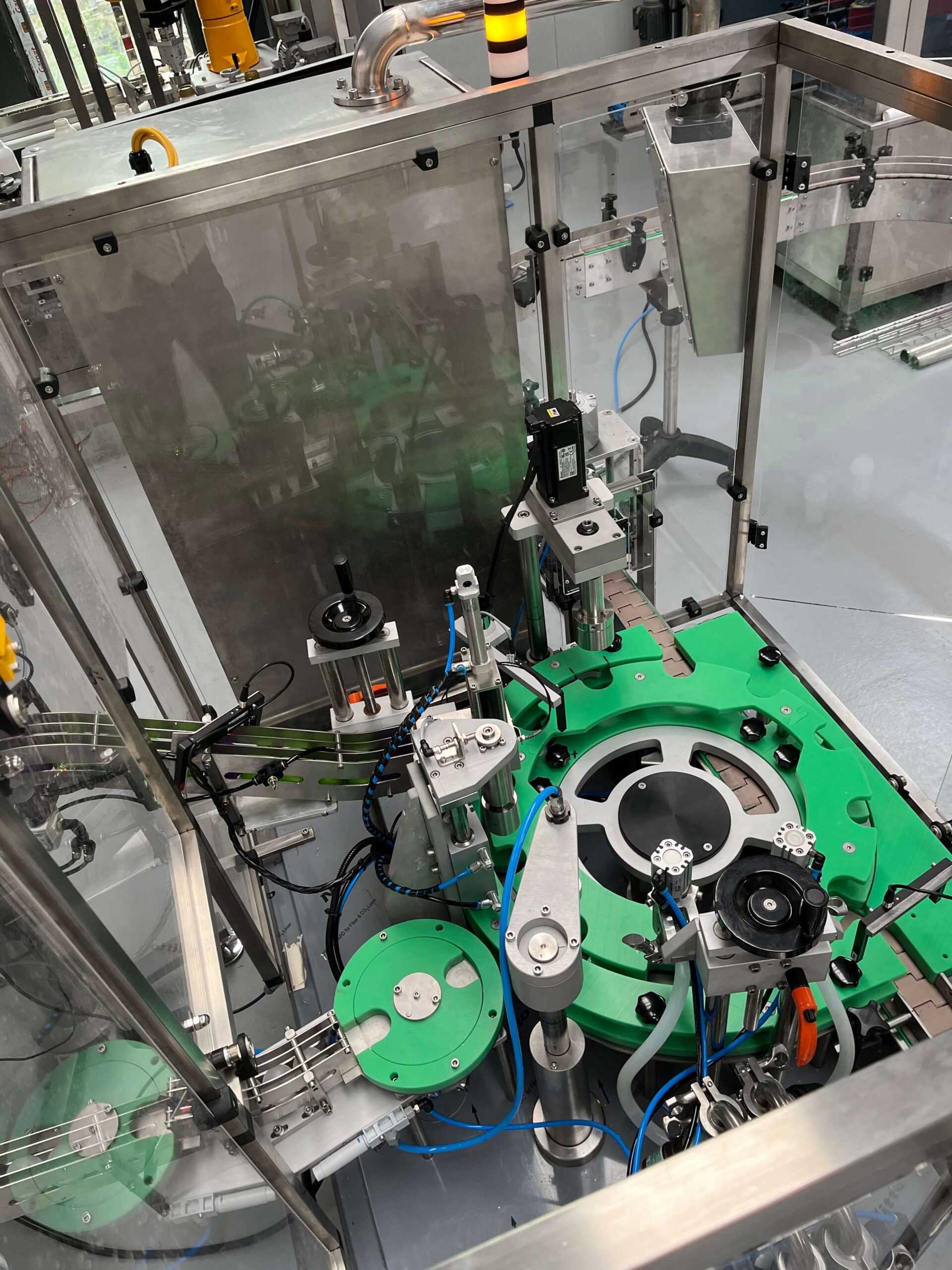

ROLL-ON FILLING AND CAPPING MACHINE

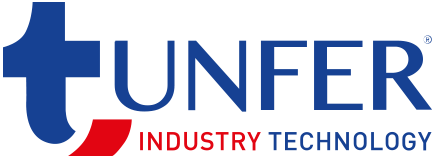

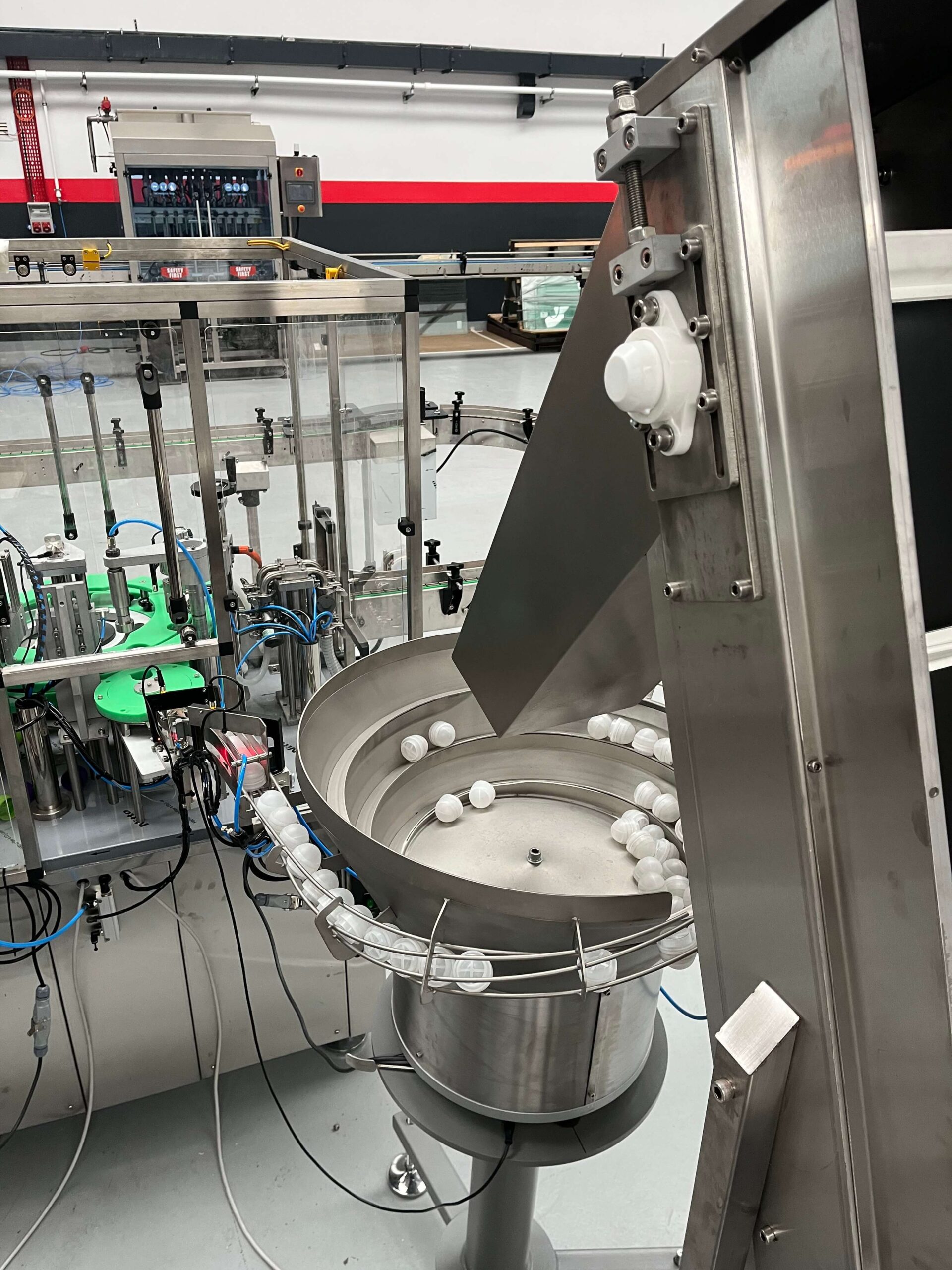

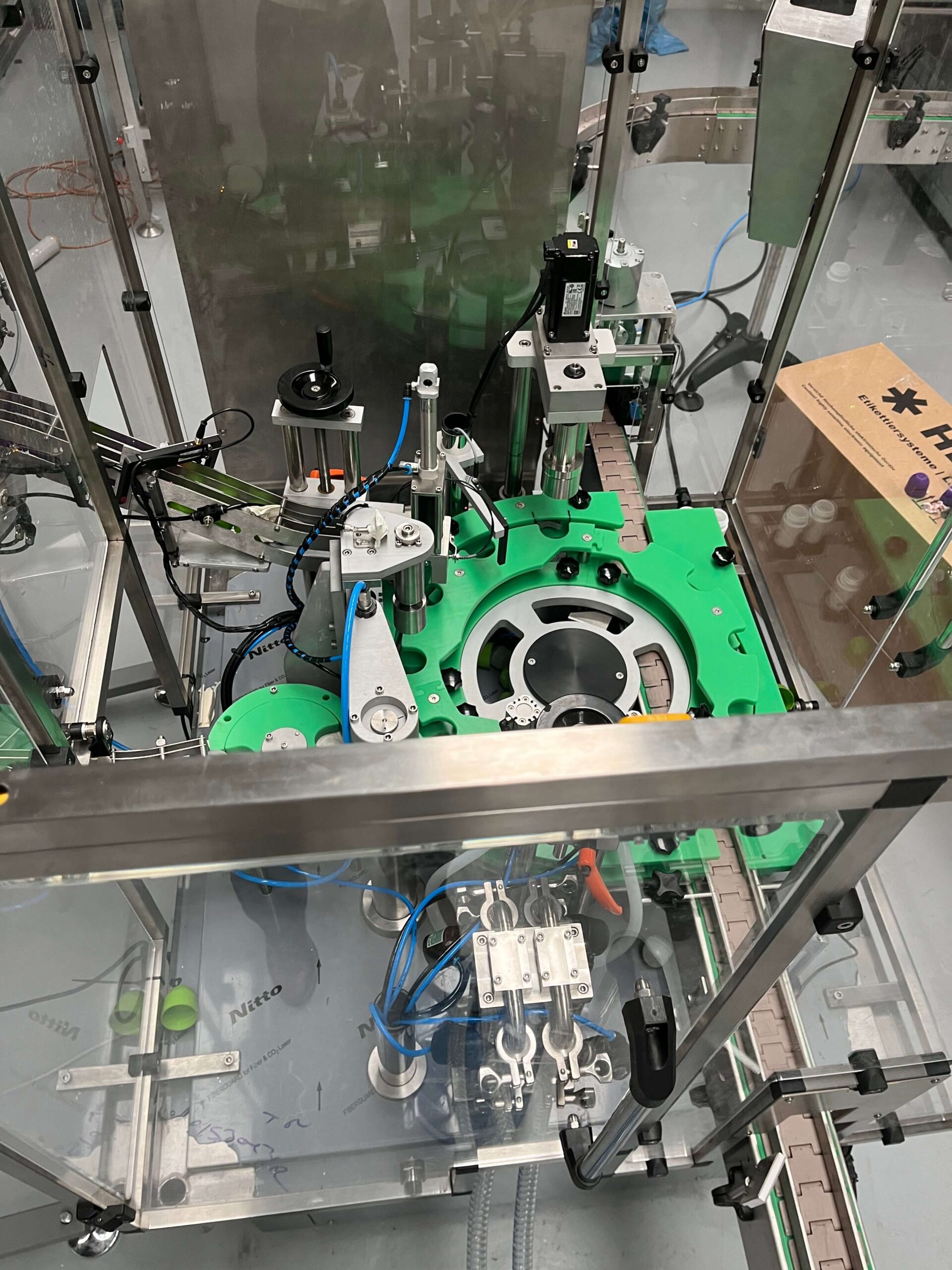

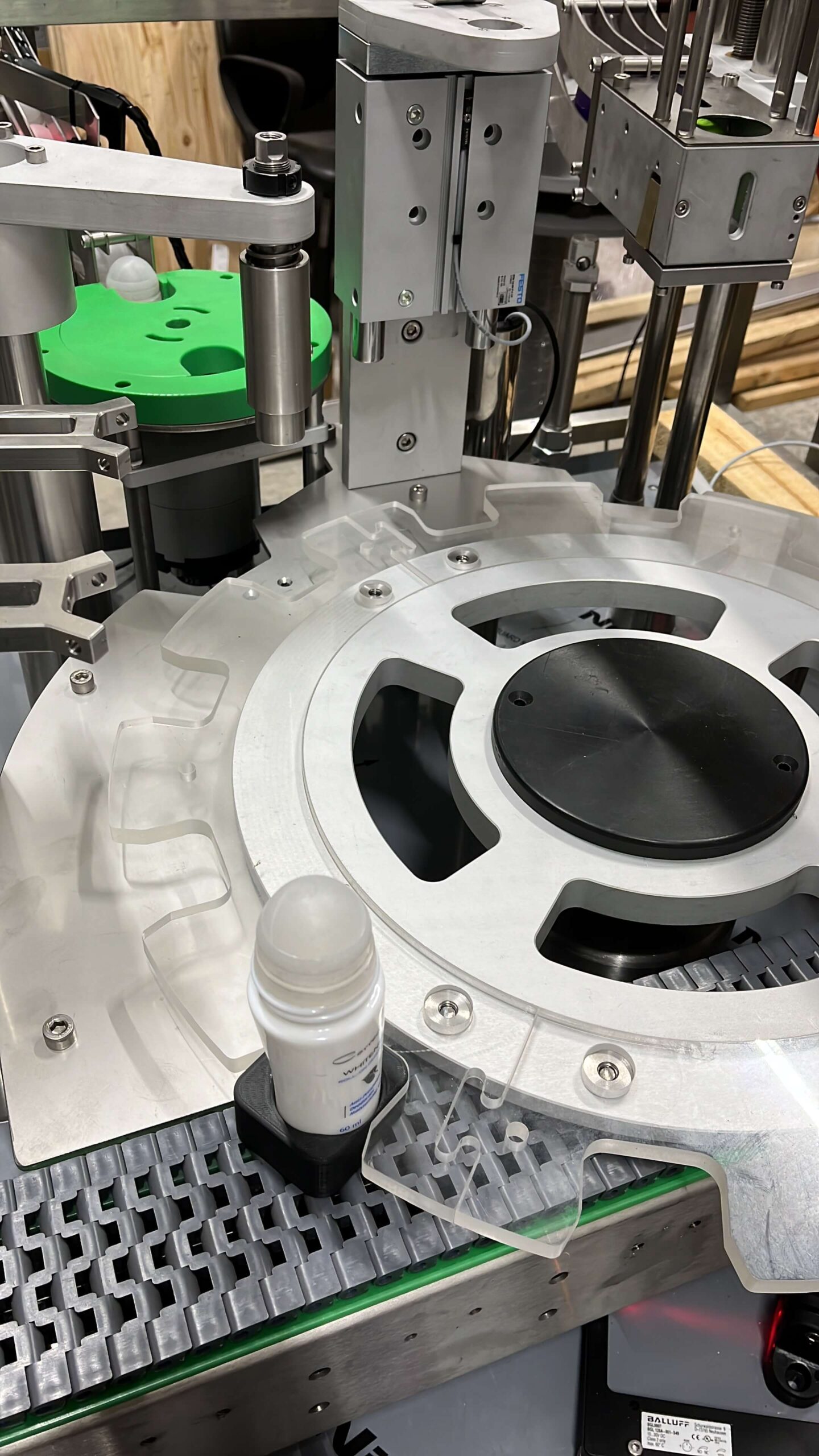

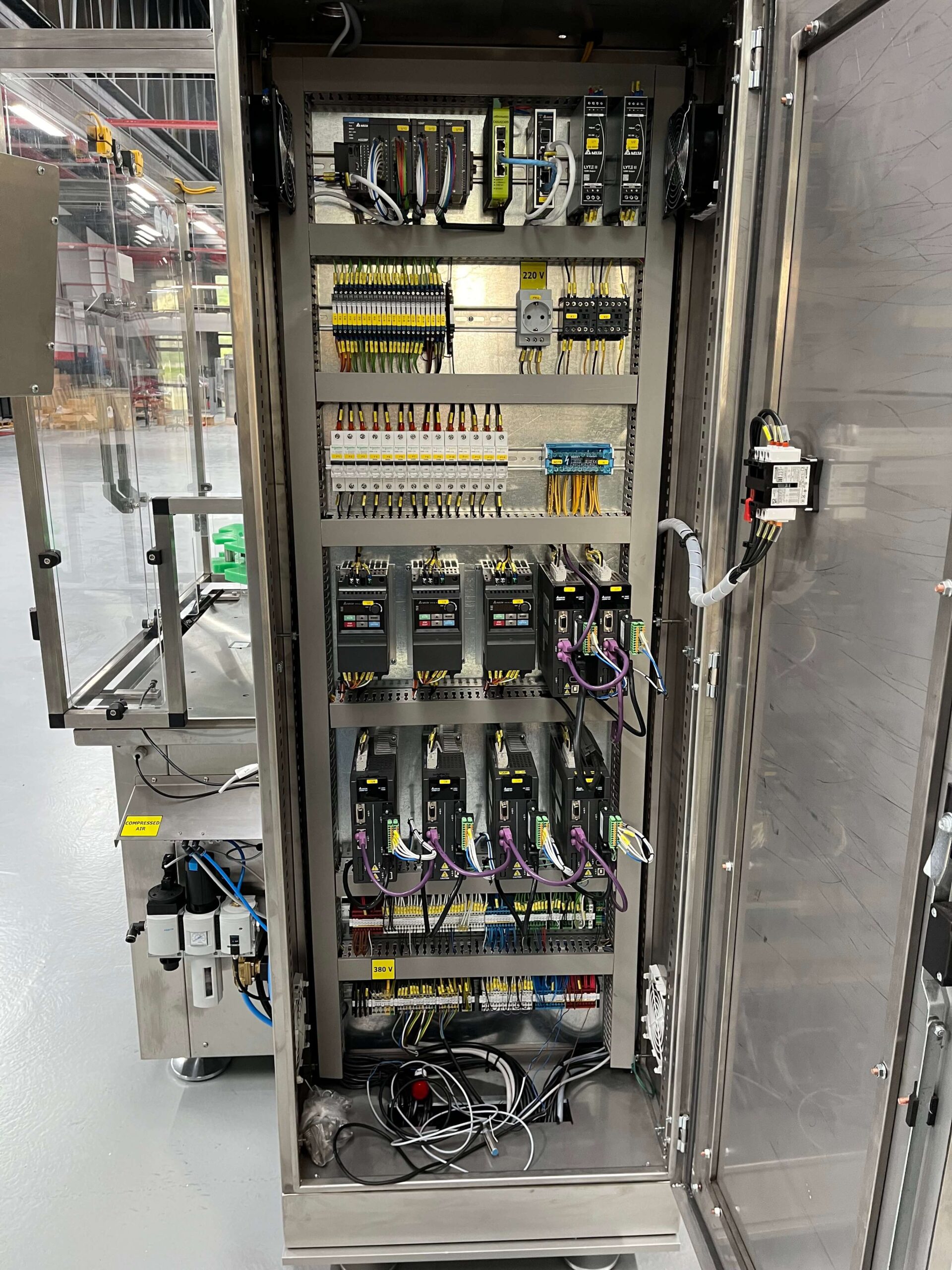

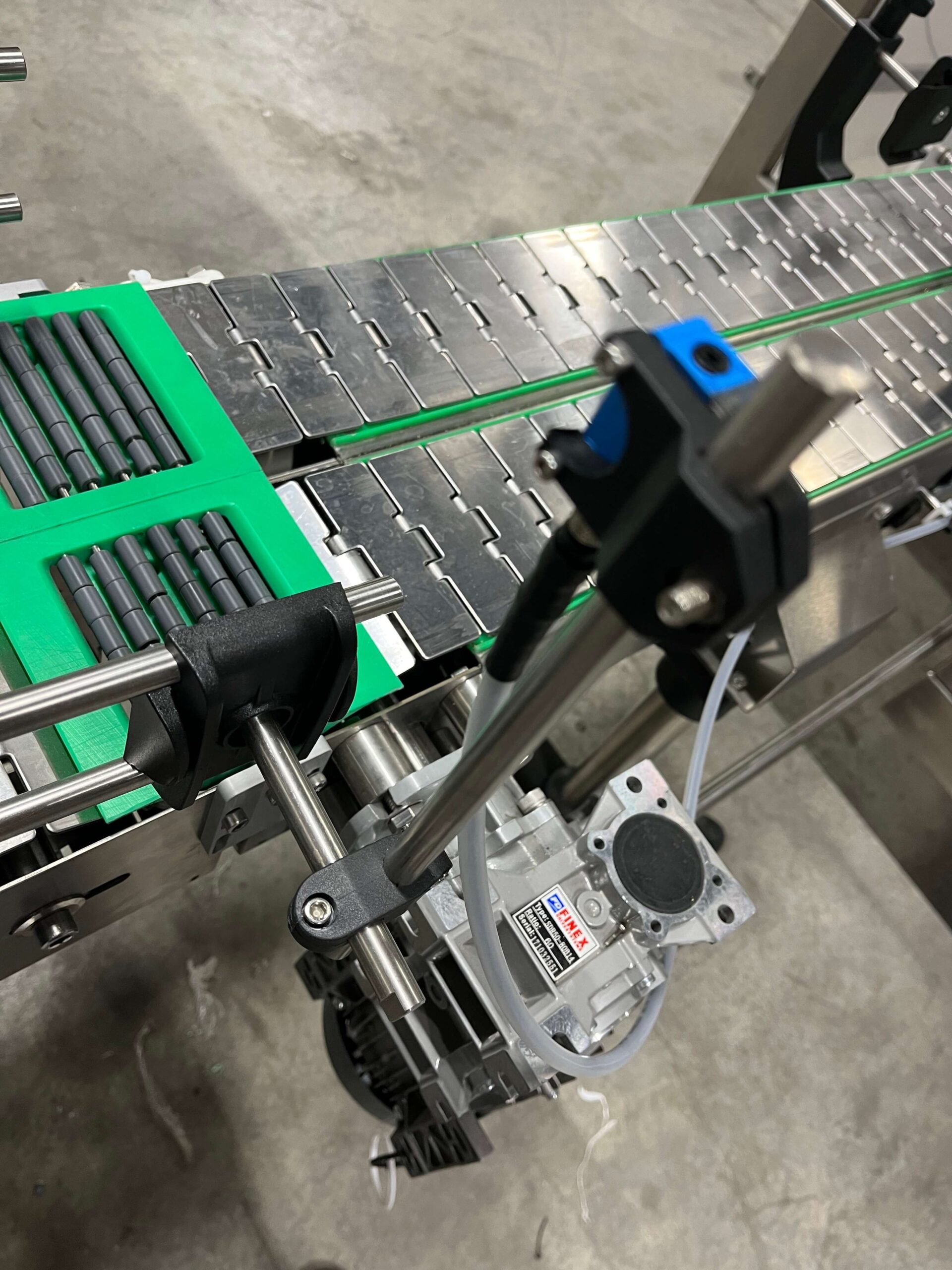

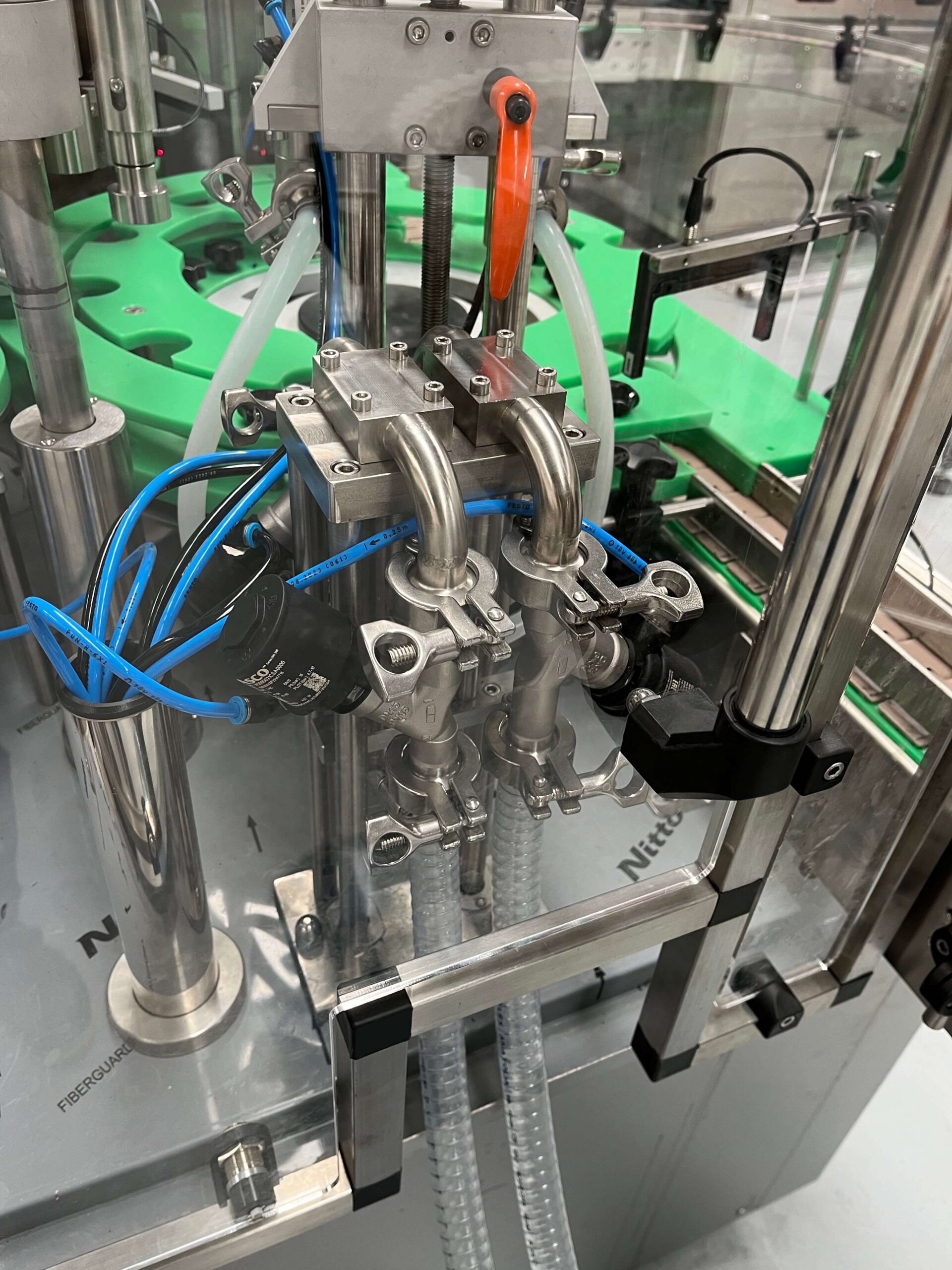

A roll-on filling and capping machine is a specialized piece of equipment designed for the efficient and hygienic filling and sealing of roll-on products, such as perfumes, essential oils, and cosmetic liquids. This machine operates by automatically filling containers with the desired product before securely capping them with roller ball applicators. The filling process is typically precise, ensuring accurate dosage and minimizing product wastage. The machine is equipped with advanced features, such as adjustable filling nozzles and conveyor systems, to accommodate various container sizes and shapes. Additionally, it incorporates hygiene standards by utilizing materials that are easy to clean and maintain, preventing contamination during the filling process. With its high-speed operation and reliable performance, a roll-on filling and capping machine enhances production efficiency and ensures the consistent quality of finished products, making it an essential tool for manufacturers in the cosmetic and personal care industries.